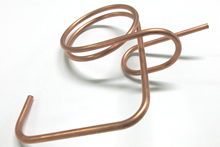

Pipes made on request

|

|

|

The continuous research in new products development allowed GS to evaluate the possibility of processing several raw materials, including copper, aluminum and steel.

GS is now able to make pipe with diameter of at least 4.76 mm and max. 30 mm.

The activities carried out every day by GS thanks to automated machines, able to make several complex shapes, are: cutting, deforming, edge processing, bending, drilling and welding.

The machine fleet, still in expansion, is composed by six machines reserved to the pipe bending and deformation. In addition, GS owns welders and drillings to meet every need. The variety of machines is essential to avoid any problem and delay in delivery.The product qualitative aspect is a crucial point on which GS always continues to invest.

Each machine is equipped with a particular test that avoids any kind of loss on the finished product; each workstation has all the devices necessary to verify each particular aspect under construction.

The constant training of its staff allows GS to have a specialized team, that takes care of the production and every aspect of this process.